Small bag dust-free unloading station is a kind of unloading equipment for small bags of powder materials. It specializes in dealing with the problem of dust overflow caused by powder materials and granular materials during the unloading process, and can achieve dust-free production sites.

National Service Hotline: 17768618000

ConsultingProduct Introduction

Small bag dust-free unloading station is a kind of unloading equipment for small bags of powder materials. It specializes in handling the problem of dust overflow caused by powder materials and granular materials in the process of unloading, and can achieve dust-free production sites.

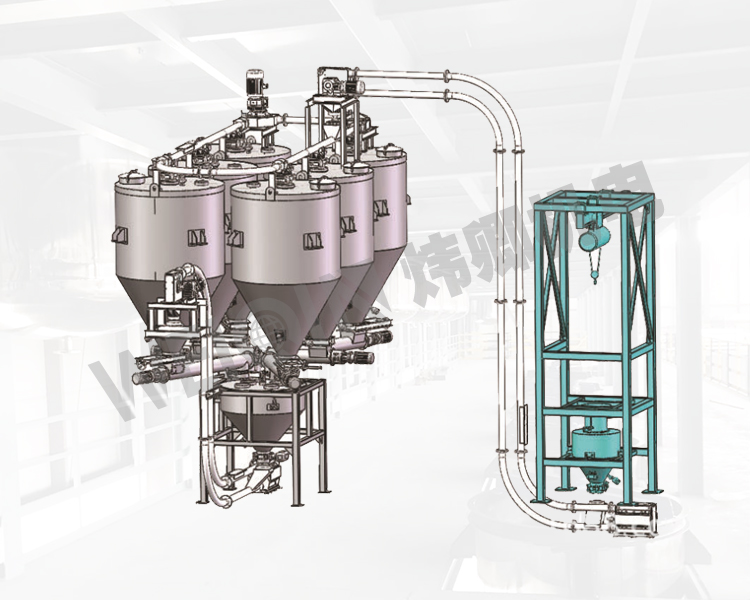

System structure

Small bag unloading and feeding station: The system is composed of manual unloading bin, pressure-proof feeding platform, unloading bin, vibrating screen, filtration system, dust collection system, blowback airbag and vibration motor.

Small bag feeding station: The system is composed of manual unloading bin, pressure-proof feeding platform, unloading bin, safety screen, filtration system, dust collection system, blowback airbag and other components.

The above auxiliary accessories can be customized freely, which is convenient for unloading.

Working principle

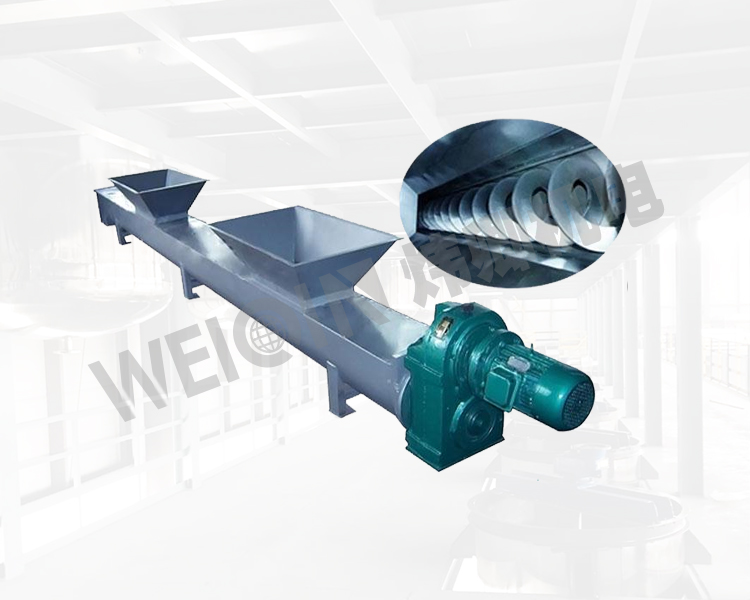

When small bags of materials need to be unpacked and poured into the next process, they only need to be directly unpacked manually and put into the system. The dust generated during feeding is collected by the dust collector. When the material passes through the vibrating screen (safety screen), the bulk material and foreign matter can be intercepted, so as to ensure that the particles that meet the requirements are discharged.

Work process

Dust collection: The small bag feeding station can realize the manual feeding process without dust spilling. The unpacked materials enter the cone inside the feeding table. The spilled dust is absorbed by the strong negative pressure airflow during the feeding process, and then blocked by the filter element , The clean gas is discharged through the fan through the filter element.

Clean the filter element: During the working process of the system, the filtration resistance of the filter element will increase due to the adsorption of the material. Therefore, a high-flow pulsed air flow is required to blow the filter element back. The blowback action automatically reverses with the proximity switch trigger system when the door is closed. blow. Reduce or remove the material adsorbed on the surface of the filter element, so that the running resistance of the fan is kept within the allowable range.

Powder conveying: The material in the cone of the small bag feeding station is conveyed to the downstream device through the negative pressure conveying system, and dust-free operation and operation can be realized on site.

It is recommended to be used in conjunction with the product vacuum feeder to achieve dust-free feeding and feeding.

The main function

1) Under the condition of air extraction by the fan, the inner cavity of the working chamber gets a certain negative pressure, and the dust generated during feeding is sucked into the filter to avoid leakage to the outside of the box. This effectively avoids direct contact between the operator and the flying dust of the material and protects the health of the operator.

2) The vibrating screen is placed inside the silo, so that the dust generated when the vibrating screen is working is concentrated in the silo, and then sucked into the filter with the fan for filtering.

3) The base of the fan and the upper part of the feeding bin are connected by flange bolts. When replacing the filter element, remove the fan and fan base. When replacing the screen or maintaining and repairing, move the fan and fan base from the upper part of the feeding bin. To reduce the weight of the upper part of the feeding bin, it is convenient for the gas spring to open, safe and reliable.

4) The door of the feeding bin is equipped with a gas spring steam opener, which is convenient for the operator to open. Sealing strips are inlaid around the warehouse door to prevent dust from flying out. After the door is closed, the blowback airbag can be used for blowback.

5) Centrifugal fan: It is the power element of the entire dust removal system, used to form a certain negative pressure to prevent dust from leaking out, and to remove the dust that is diffused when sieving materials to facilitate equipment operation.

6) Vibration motor: It is the power element of the entire blanking screening system, used to provide the vibrating screen with the excitement force

Position:

Position: